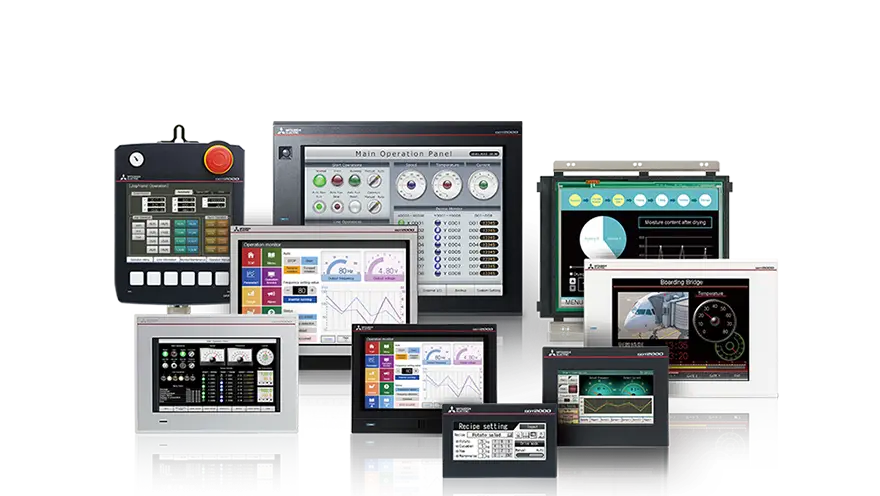

MITSUBISHI HMI

A Human Machine Interface (HMI) is a digital product that facilitates communication between operators and automated equipment. The HMI provides a variety of communication ports for seamless interaction with various devices. The touch panel allows intuitive parameter configuration, while the LCD screen displays monitoring data related to the machine equipment. Additionally, flexible editing software enables designers to create customized interface screens tailored to the specific needs of different applications.

For any service and support please contact us

Functions of HMI

Data Visualization → Shows process values (temperature, speed, pressure, etc.).

Control → Start/stop motors, change setpoints, adjust process parameters.

Alarm Management → Display faults, warnings, system errors.

Data Logging & Trending → Record production data, energy usage, fault history.

Communication → Connects PLCs, SCADA, sensors, VFDs, etc.

Applications of HMI

Applications of HMI

HMI is used anywhere machines and humans interact:

Industrial Automation: Factories, production lines, assembly machines.

Process Industries: Oil & gas, chemical plants, cement, pharmaceuticals.

Energy Sector: Power plants, wind turbines, substations.

Water/Wastewater: Pump stations, treatment plants.

Building Automation: HVAC, elevators, lighting systems.

Transportation: Trains, ships, traffic systems.

Types of HMI

Types of HMI

There are several categories depending on design, application, and connectivity:

1. Push-Button Replacer (Basic HMI)

Oldest form → replaces physical switches, indicator lights.

Example: Small text-based display on a PLC or drive.

Use: Simple machines, motor control panels.

2. Text-Based HMI

LCD/LED display with text only.

Navigation via keypad.

Use: Simple process monitoring (temperature controllers, small machines).

3. Graphical HMI

Touchscreen with graphical interface (icons, mimic diagrams).

Shows real-time process data, alarms, trends.

Use: Most modern machines, VFD panels, automation systems.

4. PC-Based HMI (Advanced)

Runs on industrial PC or tablet.

Supports advanced graphics, 3D views, data logging.

Often integrated with SCADA or MES systems.

Use: Large process plants, central monitoring rooms.

5. Web-Based / Cloud HMI

Accessible via web browser or mobile app.

Remote monitoring & control.

Use: Smart factories, Industry 4.0, IIoT applications.

HMI vs SCADA

HMI vs SCADA

HMI → Local interface (machine level).

SCADA → Supervisory system, integrates multiple HMIs + databases, used for wide-area monitoring.

Examples of HMI in Action

Examples of HMI in Action

Operator uses HMI to start a motor connected to a PLC & VFD.

HMI shows real-time motor speed, current, fault alarms.

If overload occurs → HMI displays red alarm popup with history.

Operator adjusts speed setpoint using HMI touchscreen.