POWER BBT

POWER BBT

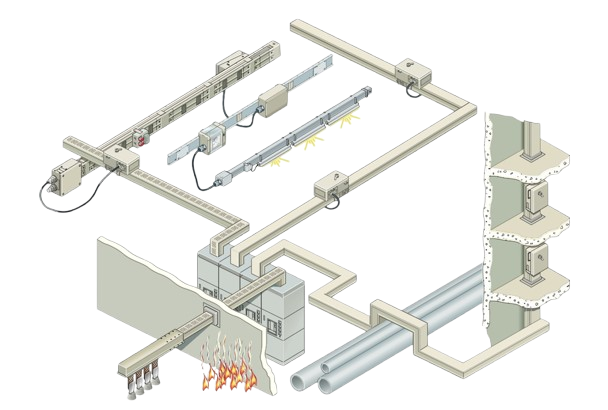

Busbar trunking systems (BBT) consist of insulated copper or aluminium busbars enclosed in a trunking. Use a specialist epoxy resin coating to insulate each conductor, the coating is applied to the busbars using an in-house developed and industry leading process. Modern busbar trunking is modular in design and is supplied in pre-fabricated lengths and available in a range of conductor configurations. The product range typically includes elbows, T-connectors, feeder units, panel flanges and various other standard or custom components that make it simple to configure for almost any application.

For any service and support contact us.

Product Features:

Easy to design power distribution and clear network structure, easy engineering and installation possibility

Law ignition energy and high short-circuit value. Fast & simple installation with minimum tools. Tap-off connections can be made to Distribution Busbar lengths; Tap-offs can be added, removed and repositioned as necessary during installation, there is no waste or scrap. So it’s environment friendly. Easily be removed and re-used where required

Product Specifications

The low impedance prefabricated horizontal & vertical BusbarTtrunking System shall be type tested assembly (TTA) conforming to IEC shall be suitable for use in installation conforming to IEC 364.

Standard of busduct | IEC |

Standard Certificate: | UL Certificate |

Rated current | 250A-6300A with 25A-40A & 100-160A Lighting Power |

Live conductor | 4W GE AL & CU |

Neutral % | 100% |

Rated insulation voltage | 1000V AC |

Withstand voltage | 10000V AC |

Frequency | 50 HZ |

Class of insulation | Class B ( 130 Deg. C ), Class F ( 155 Deg. C ), Class H ( 180 Deg. C ) |

Insulation materials | Epoxy compound insulation ( thickness 1.6 mm ) max |

Busbar materials | Aluminum / Copper |

Maximum ambient temperature | 50 Deg. C |

Degree of protection | IP54,IP55,IP65,IP66,IP67,IP68 |

Copper purity | 99.9% |

Aluminum purity | 99.9% |